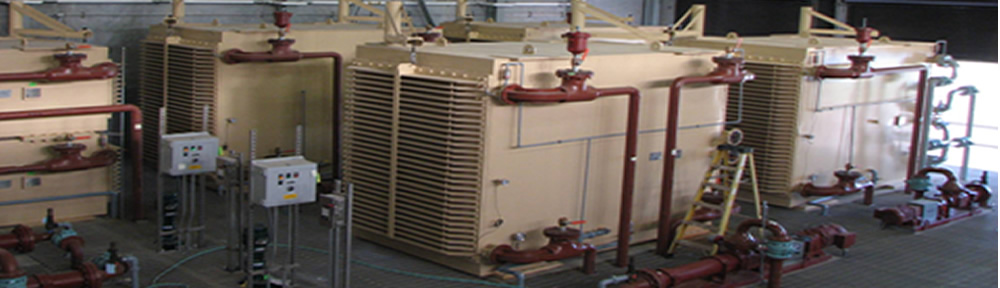

DDI is a well-established company (since 1980) experienced in the design and manufacturing of plate type.

“CUBE”™, “Square”™, NON-PLUGABLE Heat Exchangers specifically suitable for Heat Recovery from liquid waste materials containing large size solids such as Municipal Sludges & other processes.

DDI’s unique Heat Exchanger & Recovery design was developed with large capital, R&D investment and solutions provided by several top design engineers working on R&D with the Government’s help & encouragement.

These days, the Heat Recovery and Energy savings have become even more critical in every industry.

DDI has designed and installed Sludge Heat Exchangers that have been operating for as long as 7 (seven) years without the need of any maintenance.

The new DDI HE “high tech” for the WWTP (Waste Water Treatment Plants) can be used to heat sludge in a Mesophilic digester (35º C, or 95º F) or a Thermophilic digester (55º C, 134º F) or to conform to the new Class A solids disposal law, via heating to about (71º C, 160º F).

This heated sludge could only be used in our NON-PLUG Heat Exchanger to economically and efficiently RECOVER the heat, by heating the incoming cold sludge.

Our specialized type of HEAT EXCHANGERS are destined for:

A) Recovery of Wasted Heat in Sewage Treatment Plants (or other industries), by the preheating of Cold Raw Sludge with the outgoing Hot Sludge.

B) Preheating of Raw Sludge with hot liquid before introduction to the Anaerobic digesters.

C) Cooling of Digested Sludge from Thermophilic to Mesophilic.

The cost for this innovative Heat Recovery Equipment could be recovered within a few months, allowing for substantial savings to the Municipality or Industry, year after year.

With the use of DDI equipment, ENVIRONMENTAL benefits can be realized together with Reduced Maintenance Costs.

DDI has a unique Finance plan whereby the customer may pay partially from the energy saved.

DDI Exhibited at the WEFTEC 2002 show in Chicago and WEFTEC 2003 show in Los Angeles and WEFTEC 2004 in New Orleans.

DDI will be in WEFTEC 2005 in Washington.

See our website for price COMPARISON of DDI HEAT EXCHANGERS to the COMPETITION. The table illustrates, that due to maintenance costs, the competition might cost 200,120 US$ more in 10 years (or 450,560 US$ in 20 years).