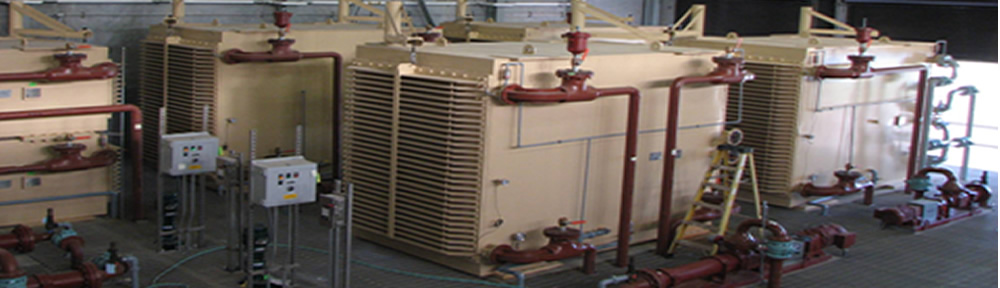

Heat recovery exchangers

Heat recovery exchangers from DDI Heat Exchangers provide non-plug operation despite stringy and sticky materials in municipal sludge. The systems reduce carbon dioxide emissions and provide unobstructed liquid flow. The compact units require a small footprint and provide reliable and maintenance-free operation. 514/696-7961; www.ddi-heatexchangers.com.

Reusing waste

Rectangular Square Cube heat exchangers from DDI-Heat Exchangers Inc. have compact, rectangular flow channels that minimize plugging. Sludge-to-sludge heat recovery exchangers, hot water-to-preheated sludge, and cold water-to-processed sludge heat exchangers are available. Systems using sludge-to-sludge heat recovery could see a payback in four to seven months.

The units have a large heat transfer surface, small footprint, more turbulence, 3-inch gaps to limit sludge blockage, full access to internals via doors, davit arms on swinging doors, optimum height for fast flow, realistic viscosity calculations, thick layers against abrasion (0.25- to 0.375-inch minimum), and a backup that uses the sludge-to-sludge heat exchangers for the water-to-sludge process. All are low maintenance. 514/696-7961; www.ddi-heatexchangers.com.

Heat-recovery exchanger

DDI heat-recovery exchangers use water and direct sludge-to-sludge heat recovery. The units are designed to be compact and efficient and limit plugging and baking. 514/696-7961; www.ddi-heatexchangers.com.

Heat exchange system

The HX heat exchanger system from DDI Heat Exchangers can connect to sewage lines and integrate into a building’s heating and ventilation system to recover heat and cooling energy from sewage. It is easy to access, low in maintenance and reliable. It can be easily integrated with existing wastewater infrastructures. 514/696-7961; www.ddi-heatexchangers.com.

Heat exchangers stop clogging and baking

Problem

Holes in three tube-in-tube heat exchangers at the Stanely Street Wastewater Treatment Plant in Niagara City, Ont., affected the heating of sludge with hot water. Heat exchanger replacements would have to fit through a 5-foot-square hatch in the roof, then be rolled down a long, winding corridor.

Solution

The facility bought rectangular-channeled heat exchangers from DDI Heat Exchangers to handle viscous material. The nonblock design has 3-inch gaps to prevent sludge blockage and no spacers for both liquids. The 3-feet-per-second flow prevents baking, while creating more turbulence for better heat transfer.

Although the units have a small footprint, their larger circumference reduces the need for macerators. A full door makes it easy to clean them every few years. DDI added a hoist bar to the exchangers for lowering them down the hatch with a crane, and rollers for maneuvering them into position.

Result

The heat exchangers are operating as specified. 514/696-7961; www.ddi-heatexchangers.com.

DDI Offers Rectangular Square Cube Heat Exchanger

The Rectangular Square Cube sludge-to-sludge heat recovery exchanger from DDI Heat Exchangers Inc. features compact rectangular flow channels for a no-plug design. The unit also has a larger heat transfer surface, small footprint and 3-inch gaps to limit sludge blockage. 514/696-7961; www.ddi-heatexchangers.com.

Heaters/Dryers/Thickeners – Direct sludge-to-sludge heat exchanger/recovery system

Large-gap heat exchangers from DDI Heat Exchangers provide non-plug operation for more than eight years. They allow for a wide gap — larger than the pipe or the pump opening — reducing the risk of plugging or blockage in the channels. Correct channel width enables fast flow to reduce the risk of baking to the surface. Outside bends increase mixing, which increases the turbulence and heat transfer without obstructing the flow. 514/696-7961; www.ddi-heatexchangers.com.

Heat Exchangers/ Recovery Systems – Wide-gap non-plug heat exchanger

Wide-gap non-plug heat exchangers from DDI Heat Exchangers have a rectangular channel structure with large gaps of more than 6 inches, allowing for a double layer between sewage and potable water. Recovered energy can be used for heating in winter and cooling in summer. 514/696-7961; www.ddi-heatexchangers.com.

DDI Heat Exchangers Provide Non-Clog Performance

Rectangular Square Cube heat recovery systems from DDI Heat Exchangers

Rectangular Square Cube heat recovery systems from DDI Heat Exchangers are designed to handle sludge with more than 26 percent solids without plugging.

Heat from sludge warmed for anaerobic digestion (95 degrees F Class B, 135 degrees F Class A) is recovered and used for direct heating of incoming cold raw material. By using direct sludge-to-sludge heat recovery, cold raw sludge can be heated to 75 degrees F before entering the digester, saving on boiler or electrical output, says Erwin Schwartz, company president.

To avoid plugging, the DDI system uses parallel 3-inch-high rectangular channels (3- to 6-inch sludge side gap and 1- to 6-inch channel water side gap). The channel width promotes fast flow and avoids the risk of baking. The funnel inlet allows passage of large, stringy, fibrous or viscous solids or debris.

Stacked layers of hot and cold sludge flow side by side for efficient heat transfer. As further insurance against fouling, high turbulence in the specially designed return bends and channels remove the stagnant internal film on the heat exchanger wall. Stacking also results in a compact footprint.

The unit is designed for high flows and very high viscosity. Two doors with removable Davit Arms, on opposite ends of the unit, swing open to provide access for cleaning if needed. Flushing connections are provided. A self-cleaning process using an external-mounted pig is available. The heat exchanger can be made from any weldable metal, including carbon steel, stainless steel, or duplex stainless steel.

The DDI unit requires minimal maintenance and can operate for seven years or more without cleaning, even at high percentage solids, although cleaning once every five years is recommended for most municipal applications. Standard and custom models are available, from small to very large. The system incorporates computerized data acquisition for system efficiency evaluation. 514/696-7961; www.ddi-heatexchangers.com.