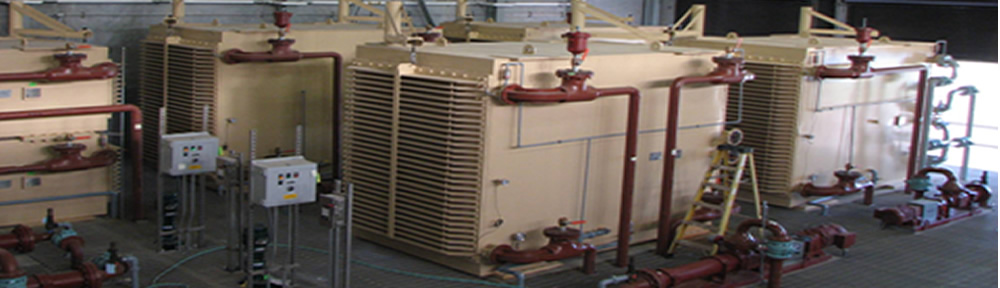

Heat Exchangers for the new North Shore Wastewater Treatment Plant Project located in North Vancouver, British Columbia, Canada

DDI Heat Exchangers to be installed at one of the biggest Wastewater Treatment Plant in North America

DDI Heat Exchangers Inc, order from LIONS GATE VANCOUVER CANADA

Eco Expo Asia 2015

Press Release, 22 Oct 2015

DDI Heat Exchangers Inc., and Energy Recovery Solution

are proud to announce:

DDI will be heading to Hong Kong to participate as an exhibitor and participant in the Environment and Green Building Trade Mission to Eco Expo Asia 2015.

DDI will also join the trade delegation of Mr. Denis Coderre, the Mayor of the City of Montreal mission to Shanghai China.

A brief (2 pages) file is on our web, with a quick summary of the Benefits and ways that the DDI very wide gap Heat Exchangers can Recover Energy in 3 different applications. In 1-Building’s Grey Water, 2- City Sewage, 3- WWTP.

https://ddi-heatexchangers.com/technical-summary/

Some of the References for the Sewage project are at bottom of the page.

https://ddi-heatexchangers.com/city-sewage-energy/

Regards Erwin Schwartz / B. Eng. / Management. President DDI-Heat Exchangers Inc Tel: 514-696-7961

Fax: 514-696-8344 Email: erwin@ddi-heatexchangers.com

WebPages:

www.energyrecoverysolution.com

DDI at the IFAT show in Munich Germany 2014

DDI Heat Exchanger Inc. announced that it has received a Letter of Intent for the Owen Sound WWTP

DDI Heat Exchanger Inc. announced that it has received a Letter of Intent for the Owen Sound WWTP.

24 February 2014.

DDI Heat Exchangers Inc Press Release.

Montreal Canada- DDI Heat Exchanger Inc. announced that it has received a Letter of Intent for the Owen Sound wastewater Treatment Plant Upgrade from J.L. Richards (in Cooperation with Conestoga-Rovers & Associates (CRA) ) to purchase a total of Three (3) DDI Rectangular Technology Heat Exchangers consisting of :

One (1) Direct-Sludge-to-Sludge Heat Recovery exchanger

- One (1) Mesophilic Heat Exchanger

- One (1) Thermophilic Heat Exchanger

Company officials are expecting the required deliveries to be within one year.

Thanks to the local Ontario Representative, Directrik Inc, who promoted the merits of the DDI Direct-Sludge-to-Sludge Heat Recovery Exchanger and the Water-to-Water heat exchangers.

About DDI

DDI has been in business since 1980 and is proud to have 39 Representatives to cover North America and other countries. (A list can be found at www.ddi-heatexchangers.com).

DDI System has been tested for more than 9 years of continued use without any plugging issues.

DDI has the following main advantages: large heat transfer surface, small foot print, more turbulence flow, gaps of 3 inches minimum to limit the sludge blockage, full access to internals via ECPS Cleaning ports, optimum height for fast flow, realistic viscosities calculations, thick layers against abrasion (0.25” min), a backup that is also able to use the sludge-to-sludge heat exchangers for the water-to-sludge process and very low maintenance.

Erwin Schwartz / B. Eng. / President

DDI- Heat Exchangers Inc

Tel: 514-696-7961, Fax: 514-696-8344

Email: erwin@ddi.ca WebPage: www.ddi-heatexchangers.com

“RECTANGULAR, SQUARE, CUBE” TM

Don’t WASTE the WASTE, use DDI HEAT RECOVERY Exchangers

HX Heat Exchanger Systems from DDI Heat Exchangers

DDI Heat Exchangers Inc announced that Directrik Inc. has done it again!

The Region of Waterloo, through its Consultants AECOM, has awarded Contract #4, in January 2012 to complete a $ 118 Million Project of the WATERLOO Wastewater Treatment Facility. Directrik Inc. will be supplying (2) DDI Heat Exchangers with Rectangular channels, and very wide gaps, capable of providing 5 MBTUH each.

Aecom has based their Heat Exchanger design on DDI’s

“Rectangular, Square, Cube”TM Heat Exchangers because of the Tight Space and NON plug requirements.

Several Heat Exchangers were considered including Tube and Tube Heat Exchangers for this project. As this was a fast track project, Drawing submittals, Delivery and Price played a major part in the Mechanical Contractors decision to go with DDI Heat Exchangers Inc.

About DDI.

DDI has been in business since 1980 and is proud to have 38 Representatives to cover North America.

(A list can be found at www.ddi-heatexchangers.com).

DDI System has been tested in North America for more then 9 years of continues use without any plugging what so ever.

DDI has the following main advantages: large heat transfer surface, small foot print, more turbulence, gaps of 3or 5 or more, inches to limit the sludge blockage, full access to internals via doors, Davit Arms for swinging the doors to save space, optimum height for fast flow, realistic viscosities calculations, thick layers against abrasion (0.25” min), a backup that is also able to use the Sludge-to-Sludge heat exchangers for the Water-to-Sludge process, and very, very low maintenance.

Erwin Schwartz / B. Eng. / President

DDI- Heat Exchangers Inc

“RECTANGULAR, SQUARE, CUBE” TM

Don’t Waste the Waste, Use DDI HEAT RECOVERY.

DDI Heat Exchangers Provides 3 rectangular Channeled heat exchangers to Niagara Region

DDI wants to congratulate Sam Directo and his team in Directrik Inc for the 3 Heat Exchangers installation in TWO Niagara Region Waste Water Treatment Plants.

Some pictures are attached showing the DDI Heat Exchanger being inserted in a VERY Narrow Hatch and in the Narrow Corridors.

Erwin Schwartz / B. Eng. / President

DDI- Heat Exchangers Inc, (since 1980)

Tel: 514-696-7961, Fax: 514-696-8344

Email: erwin@ddi.ca WebPage: www.ddi-heatexchangers.com