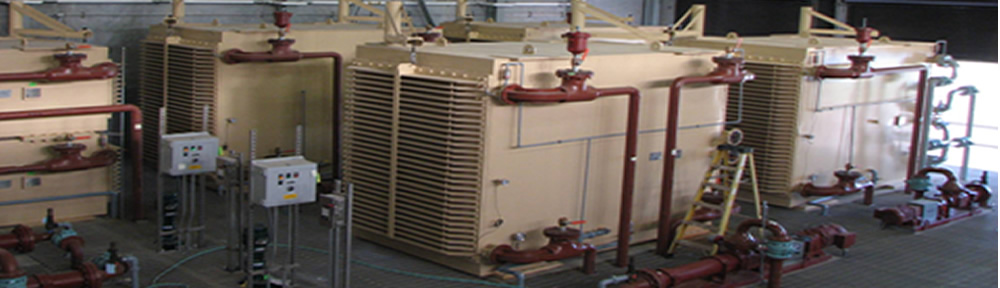

The Region of Waterloo, through its Consultants AECOM, has awarded Contract #4, in January 2012 to complete a $ 118 Million Project of the WATERLOO Wastewater Treatment Facility. Directrik Inc. will be supplying (2) DDI Heat Exchangers with Rectangular channels, and very wide gaps, capable of providing 5 MBTUH each.

Aecom has based their Heat Exchanger design on DDI’s

“Rectangular, Square, Cube”TM Heat Exchangers because of the Tight Space and NON plug requirements.

Several Heat Exchangers were considered including Tube and Tube Heat Exchangers for this project. As this was a fast track project, Drawing submittals, Delivery and Price played a major part in the Mechanical Contractors decision to go with DDI Heat Exchangers Inc.

About DDI.

DDI has been in business since 1980 and is proud to have 38 Representatives to cover North America.

(A list can be found at www.ddi-heatexchangers.com).

DDI System has been tested in North America for more then 9 years of continues use without any plugging what so ever.

DDI has the following main advantages: large heat transfer surface, small foot print, more turbulence, gaps of 3or 5 or more, inches to limit the sludge blockage, full access to internals via doors, Davit Arms for swinging the doors to save space, optimum height for fast flow, realistic viscosities calculations, thick layers against abrasion (0.25” min), a backup that is also able to use the Sludge-to-Sludge heat exchangers for the Water-to-Sludge process, and very, very low maintenance.

Erwin Schwartz / B. Eng. / President

DDI- Heat Exchangers Inc

“RECTANGULAR, SQUARE, CUBE” TM

Don’t Waste the Waste, Use DDI HEAT RECOVERY.