ENERGY RECOVERY FROM WASTED GREYWATER

Heat exchangers stop clogging and baking

Problem

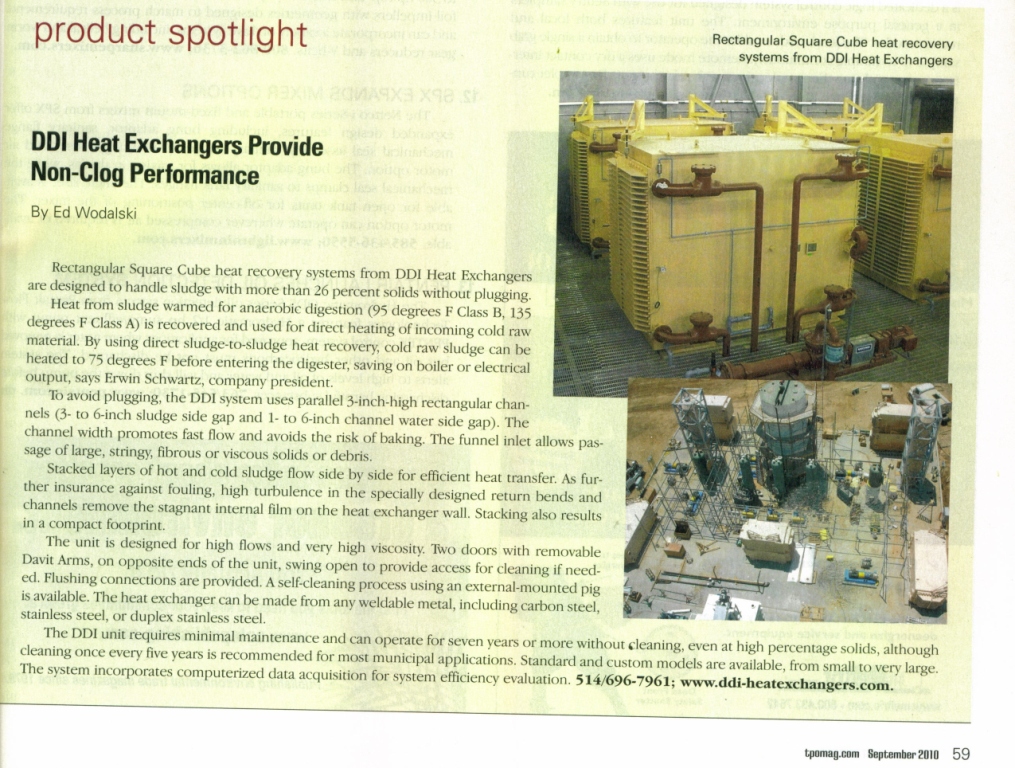

Holes in three tube-in-tube heat exchangers at the Stanely Street Wastewater Treatment Plant in Niagara City, Ont., affected the heating of sludge with hot water. Heat exchanger replacements would have to fit through a 5-foot-square hatch in the roof, then be rolled down a long, winding corridor.

Solution

The facility bought rectangular-channeled heat exchangers from DDI Heat Exchangers to handle viscous material. The nonblock design has 3-inch gaps to prevent sludge blockage and no spacers for both liquids. The 3-feet-per-second flow prevents baking, while creating more turbulence for better heat transfer.

Although the units have a small footprint, their larger circumference reduces the need for macerators. A full door makes it easy to clean them every few years. DDI added a hoist bar to the exchangers for lowering them down the hatch with a crane, and rollers for maneuvering them into position.

Result

The heat exchangers are operating as specified.

http://www.tpomag.com/

http://www.tpomag.com/

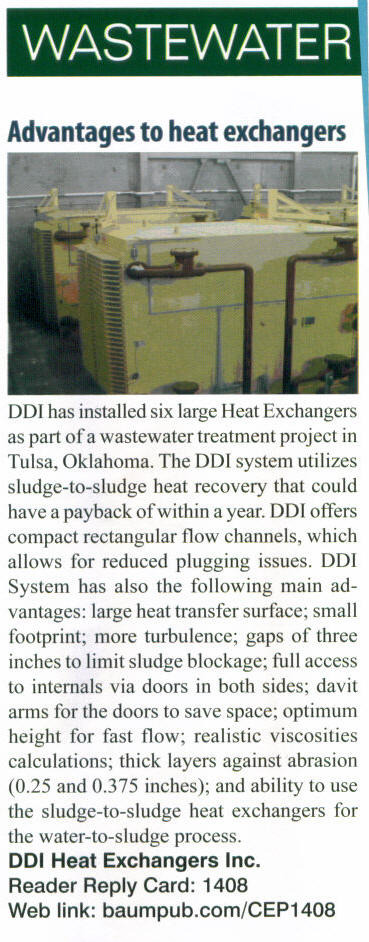

DDI Offers Rectangular Square Cube Heat Exchanger

The Rectangular Square Cube sludge-to-sludge heat recovery exchanger from DDI Heat Exchangers Inc. features compact rectangular flow channels for a no-plug design. The unit also has a larger heat transfer surface, small footprint and 3-inch gaps to limit sludge blockage. 514/696-7961 514/696-7961; www.ddi-heatexchangers.com.