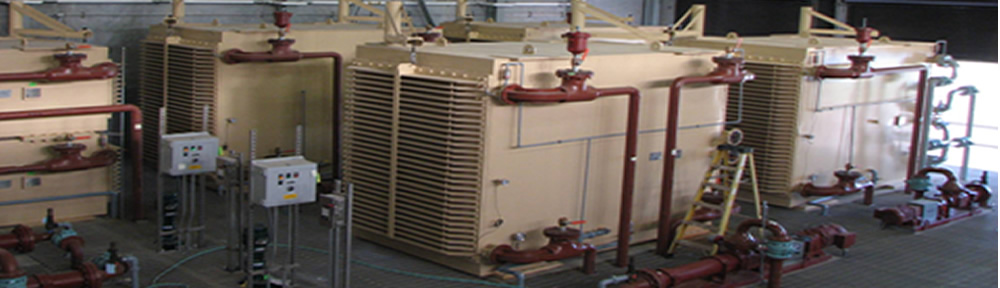

The 3 key advantages of our DDI technology are due to our Patented Technology of Rectangular channeled heat exchangers.

It is not the common tube-in-shell technology nor the common Spiral structure of heat exchangers.

1- We can control the Height or GAP of the rectangular channel.

So if we make it larger than the opening of the pump which flows the sewage or grey water or waste water or laundry or any other liquid with high % solids, than our heat exchangers will not get plugged.

We demonstrated that with 26% solids liquid flowing in our heat exchangers via a project with reference from HDR Engineering.

Therefor we can also recover the wasted heat or coolant from the city Sewage that flows below the street without plugging. With ROI of 1-2 years.

2- Due the Rectangular channel. We can control how wide to make the WIDTH of the channel so as to achieve high flows, so we lower the risk of BAKING to the surface.

Again with HDR Engineering we had liquid flows at 600 deg f without BAKING to the surface.

We can have both liquids to have very high % of solids. The hot wasted processed sludge can recover its heat to the cold raw sludge entering the waste water treatment plant with a ROI of 5-8 month.

3- Because of the Rectangular channels we can have double plates in between the 2 liquids. That allows us to comply with the law requiring double wall between the hot wasted dirty grey or black water leaving the high rise hotel or large condo building. And between the clear water on the other side of the heat exchanger which we preheat before it flows to the central boiler.

Therefore we can recover the wasted grey water in large buildings that other technologies can not do.

ROI is about 1-2 years, depending on the hotel size.