Clean Energy

Recovering Wasted Energy: Beneath the city streets

By Erwin Schwartz

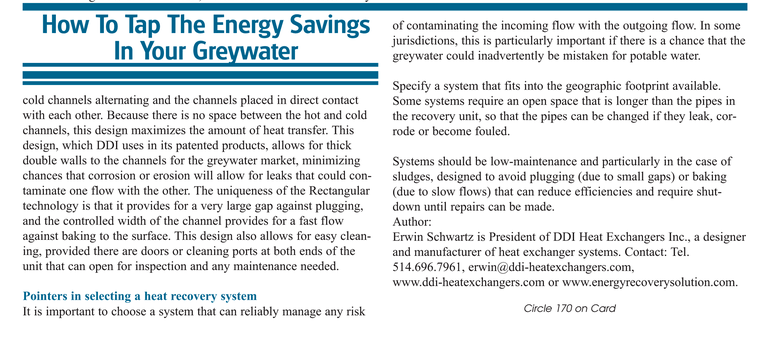

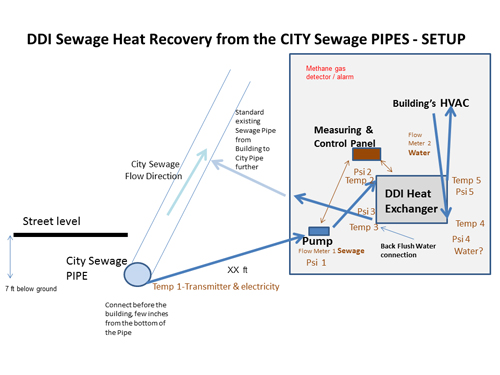

Sewage heat recovery graphNo one likes to think about it, but city planners and engineers often have no choice but to deal with it, and that’s sewage. Though techniques vary somewhat from place to place and from facility to facility, sewage generally flows down pipes with multiple steps in place designed to remove and treat as many solids as possible, before returning the freshly distilled water to the environment.

This may seem obvious, however, what might be less apparent is that the sewage flowing in pipes under city streets is hotter than the above air in the winter and colder during the summer months. With it comes along a large amount of recoverable energy that’s readily available in nearly every city worldwide. This recoverable energy could be tapped as a heat source for nearby buildings, then used in central boilers to heat surrounding infrastructure in the winter and to cool the space in the summer.

One issue that’s potentially been preventing use of this available power source is the law. For health and safety, most city laws require a double-walled separation between dirty sewage water (i.e. grey water) and clean, drinkable water, which would flow to the central boiler from on the other side of a heat exchanger.

Current technologies that could support recovered city sewage energy, such as spiral and tube-in-shell heat exchangers, unfortunately cannot have double-walled structures if they are to allow for the efficient heat transfer between liquids. Such technologies, in this case, would also have the problems of debris blockages, long with related screening costs.

Even if a heat exchanger could be developed to overcome this challenge, another issue exists. That’s how to connect a city sewage pipeline—of some 18″ to 96″, or more—directly to the heat exchanger. If the connection is made too close to the bottom of the sewage pipe, there’s the risk debris will simply plug-up the heat exchanger. If the connection is made too high, however, there will be no flow at all in dryer weather.

Finding a solution

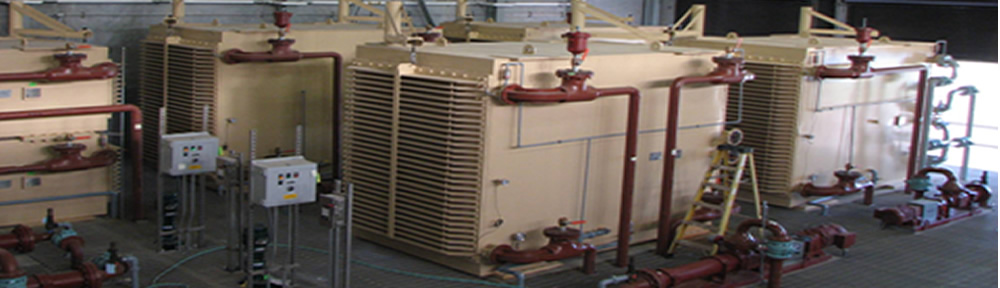

To help solve these challenges and find a solution for capturing wasted city energy, a patented structure is now available that was actually developed over a decade ago for use in wastewater treatment plants. This solution can aptly be applied to the sewage pipes below buildings and city streets, as well. These rectangular, wide-gap, non-plug heat exchangers are designed in such a way as to allow an additional plate, thereby safely permitting the separation of two liquids (the grey water and the drinking water) and meeting city laws and regulations. They can also do so without any major heat-transfer loss.

This technology structure has large, wide gaps of 6″-plus, which allows for fast liquid flows, lowering risks of blockages or baking to the surface. It even has a plastic see-through pipe section, allowing engineers to view at what conditions the flow fills up the pipe.

Although this technology has now been used successfully for energy recovery solutions, a major obstacle to overcome has been leveraging the sewage when a city’s pipeline is located far away and/or very deep under the pump. (The technology has since been tested with distances of over 320 feet away, and connections 20 feet below street level.)

Another challenge has been to find a pump that at start-up only sucks up air (no water), as it’s important to first empty the long pipe of air between the heat exchanger and the city pipe to ensure proper flow. Additionally, it’s necessary for the pump to have a reverse-flow option, lest a blockage ever occur.

Case-in-point

With the support of the Quebec Government and the City Sewage Authorities in Canada, the first-ever, direct city sewage energy recovery system in the world is now in use at an indoor soccer building in Quebec City. To date, the project is successful and what was once “lost” energy is now being recovered.

The project’s points of interest:

• The law is complied with, thanks to a rectangular, non-plug heat exchangers—and so far so good! There’s no plugging inside the heat exchanger or inside the pipes;

• After a feasibility study in the area, the ideal space was selected that provides for enough distance upstream for a connection, so as to avoid the risk of a closed-loop flow. It’s also not too far away, to ensure the costs of digging and connecting are kept affordable;

• Multiple safety features are in place to avoid the risk of dirty sewage flowing to the outside of the building (as it was necessary to vent the air out from the pipes before the sewage flows at start-up). Plus, air-liquid valves and flow detection floaters are in place, along with a computerized control panel for safety shutdown procedures;

• An Easy Cleaning Process System (ECPS) is in place, allowing the two separate channels to be cleaned within seconds; and

• The wide-gap heat exchanger provided the capability to utilize the direct flow from the city sewage, thereby saving heavy costs often incurred by indirect technologies (such as land acquisition, additional holding tanks, or heat loss form unrecovered waste).

The Quebec City installation was completed earlier this year, with ongoing data being collected. A related report will be released next year.

View additional installation photos at https://ddi-heatexchangers.com/city-sewage-energy

DDI-Heat Exchangers Inc.

http://www.ddi-heatexchangers.com | http://www.energyrecoverysolution.com

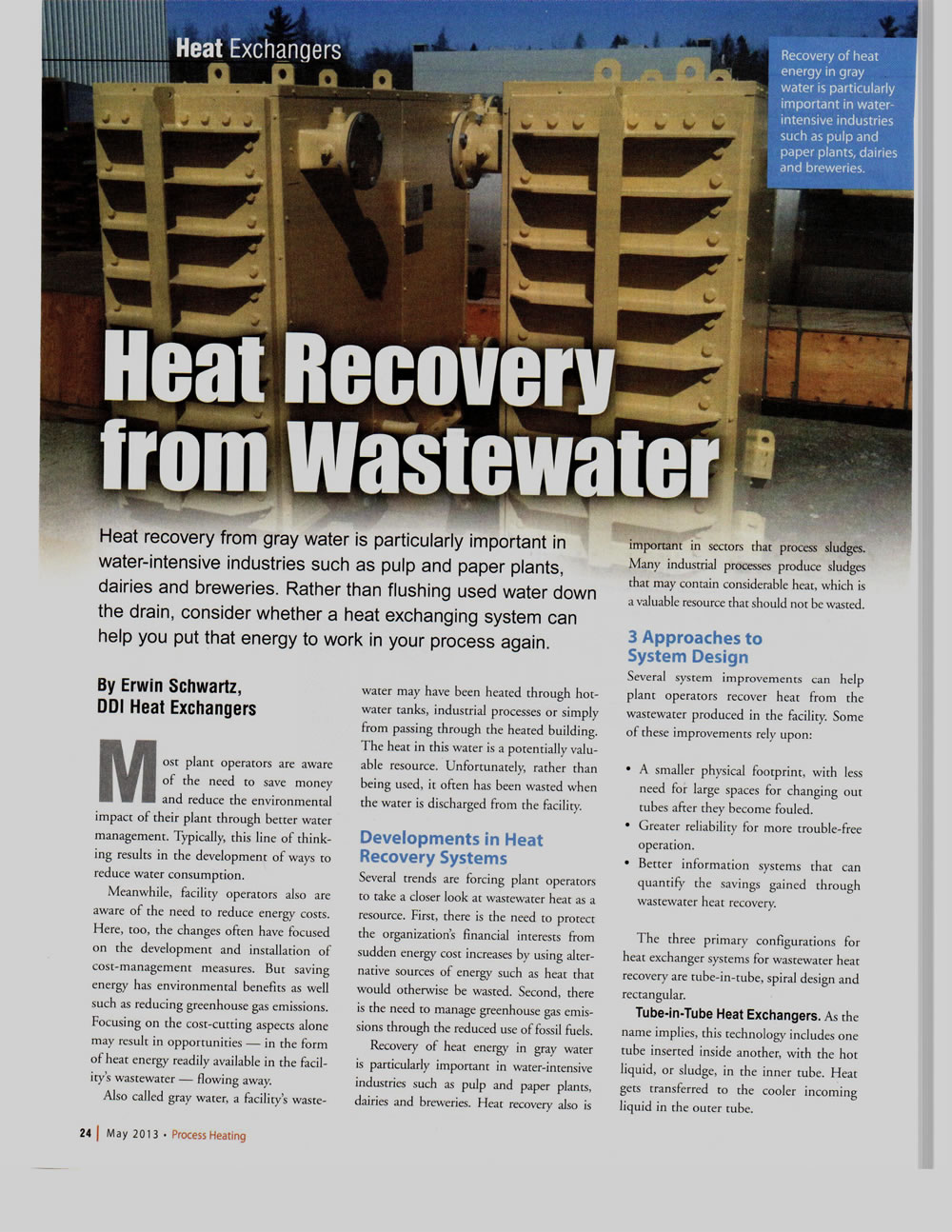

ENERGY RECOVERY FROM WASTED GREYWATER

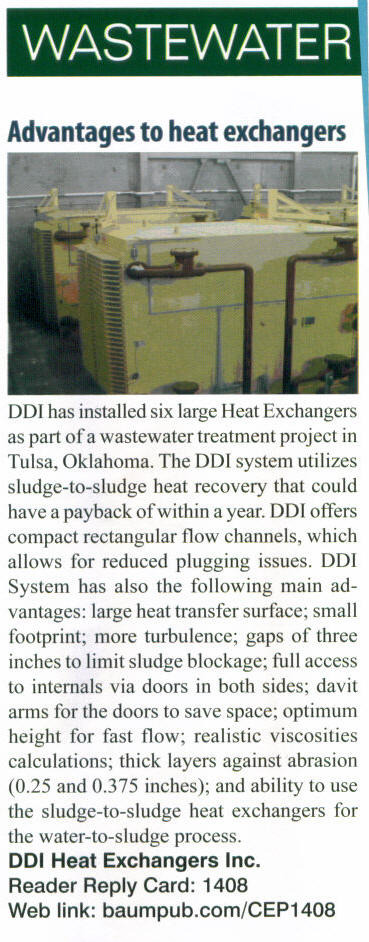

Heat exchangers stop clogging and baking

Problem

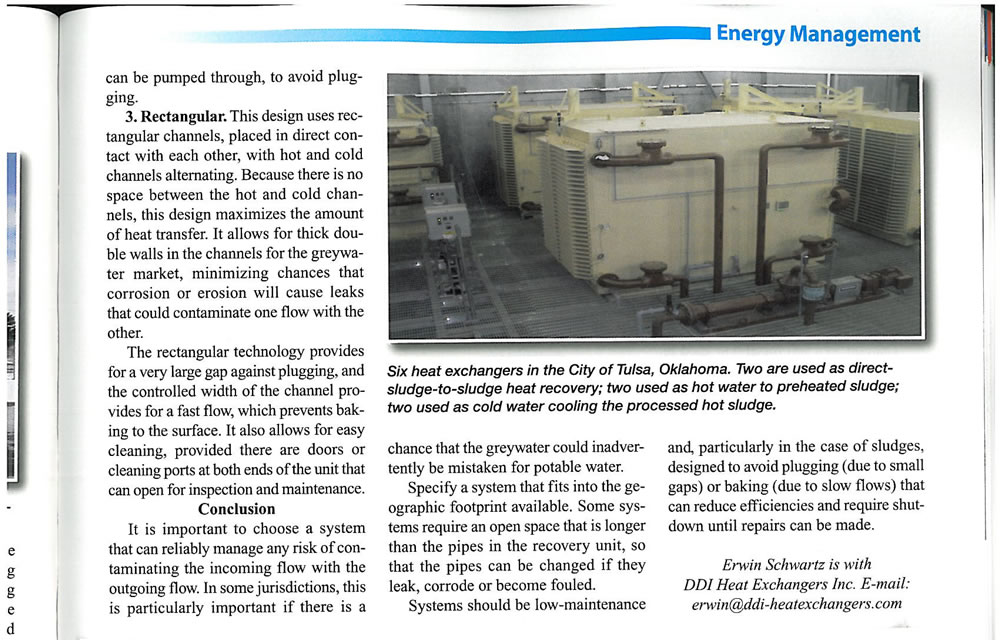

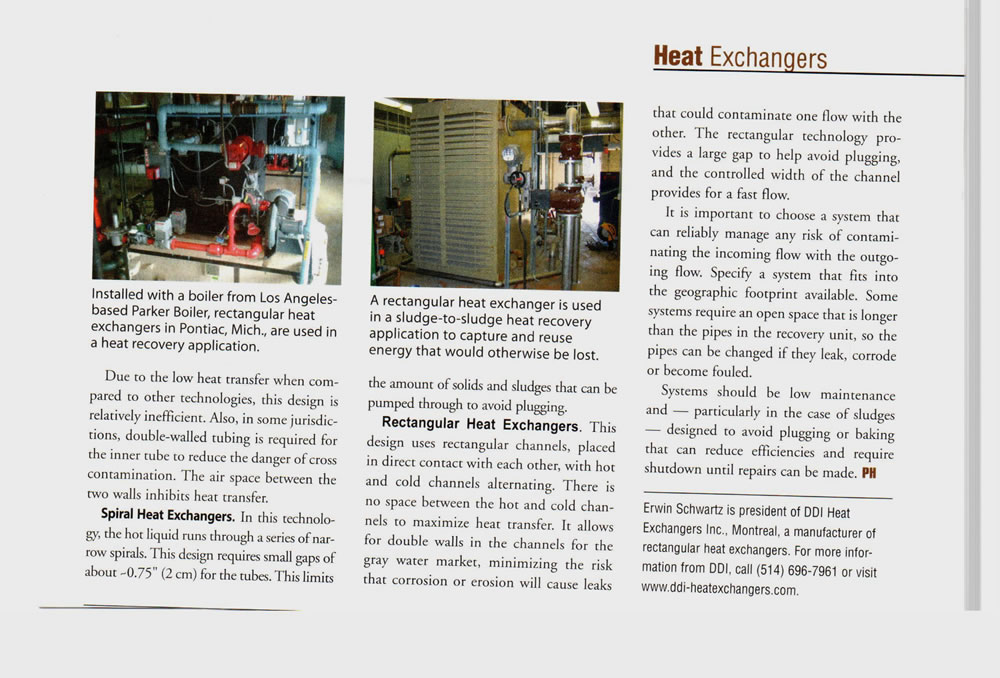

Holes in three tube-in-tube heat exchangers at the Stanely Street Wastewater Treatment Plant in Niagara City, Ont., affected the heating of sludge with hot water. Heat exchanger replacements would have to fit through a 5-foot-square hatch in the roof, then be rolled down a long, winding corridor.

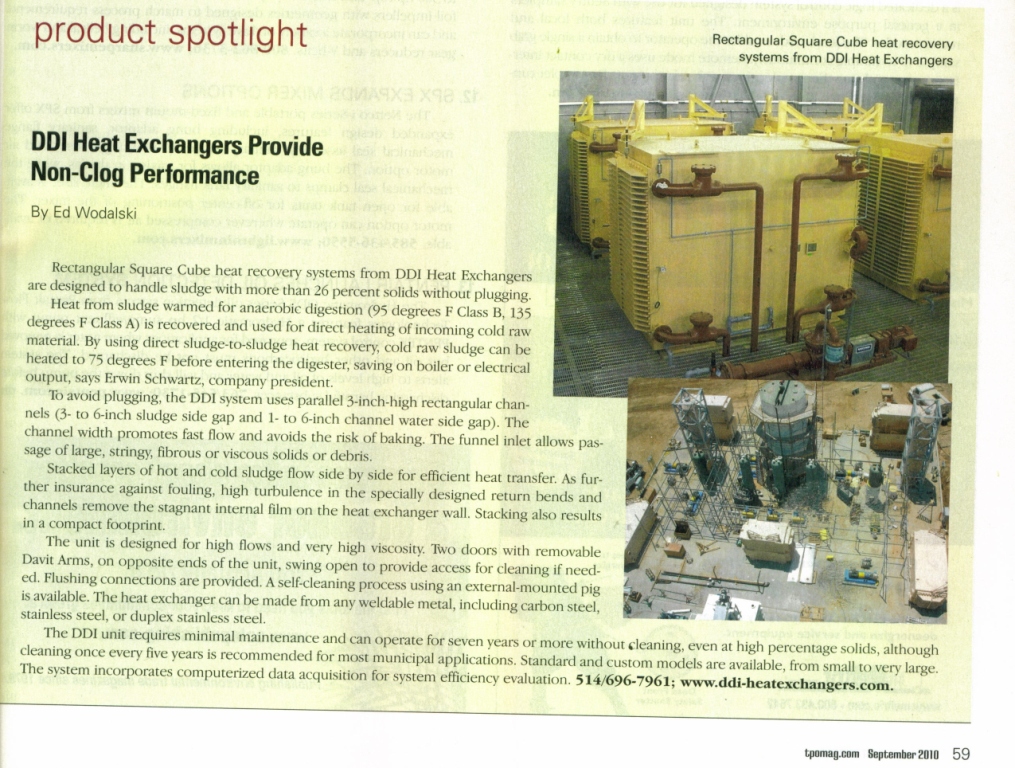

Solution

The facility bought rectangular-channeled heat exchangers from DDI Heat Exchangers to handle viscous material. The nonblock design has 3-inch gaps to prevent sludge blockage and no spacers for both liquids. The 3-feet-per-second flow prevents baking, while creating more turbulence for better heat transfer.

Although the units have a small footprint, their larger circumference reduces the need for macerators. A full door makes it easy to clean them every few years. DDI added a hoist bar to the exchangers for lowering them down the hatch with a crane, and rollers for maneuvering them into position.

Result

The heat exchangers are operating as specified.

http://www.tpomag.com/

http://www.tpomag.com/

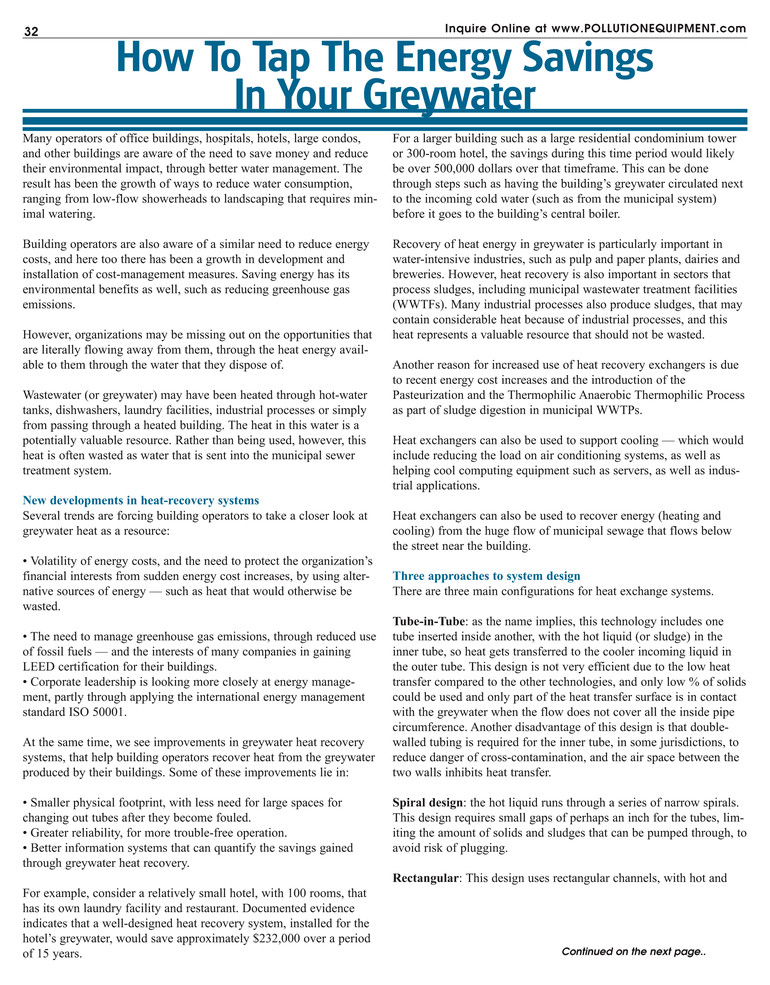

DDI Offers Rectangular Square Cube Heat Exchanger

The Rectangular Square Cube sludge-to-sludge heat recovery exchanger from DDI Heat Exchangers Inc. features compact rectangular flow channels for a no-plug design. The unit also has a larger heat transfer surface, small footprint and 3-inch gaps to limit sludge blockage. 514/696-7961 514/696-7961; www.ddi-heatexchangers.com.