DDI the manufacturer of the “Rectangular Square Cube” TM Channeled, Low Maintenance, Heat Exchangers & HEAT RECOVERY, is proud to announce that;

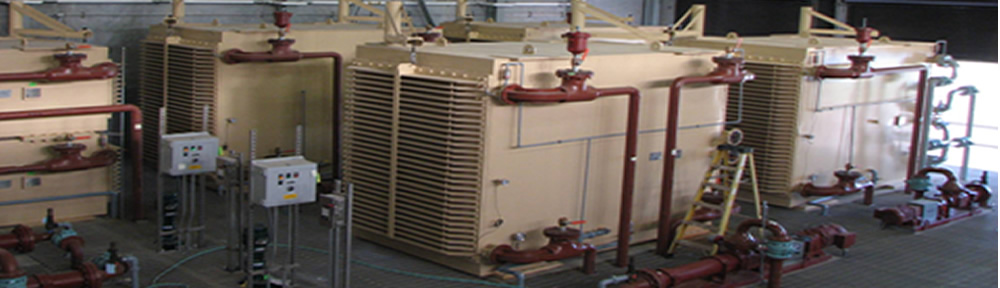

DDI installed 6 Large Heat Exchangers via Ashbrook Simon-Hartley, of Houston TX, for their ECO-THERM Process Design in Tulsa OK.

This project was with the cooperation of HDR Engineering Inc of Dallas TX and Tulsa City WWTP.

There are Sludge-to-Sludge Heat Recovery Exchangers and Hot Water-to-Preheated Sludge and Cold Water-to-Processed Sludge Heat Exchangers. The system utilizes Sludge-to-Sludge Heat Recovery that could have a payback of within a year.

DDI has a compact Rectangular flow Channels, which allows for a No Plug design, or at least for much, much less plugging, then any other technology. It Is made in USA or Canada.

DDI System has also the following main advantages; Large Heat Transfer Surface, Small foot print, More Turbulence, Gaps of 3 Inches to limit the sludge blockage, Full access to internals via Doors in both sides, Davit Arms for the doors to save space, Optimum Height for fast flow, Realistic Viscosities calculations, Thick Layers against Abrasion (0.25” & 0.375”), Back up of being able to use the Sludge-to-Sludge Heat Exchangers also for the Water-to-Sludge process, Tested for 9 years in North America, and has Very Low Maintenance.

DDI is proud to have 39 REPRESENTATIVES to cover North America.

(A list could be found at www.ddi-heatexchangers.com.).

In this latest design a Pig Cleaning System was incorporated to work with the DDI Rectangular channels.

Erwin Schwartz / B. Eng. / President

DDI- Heat Exchangers Inc, (since 1980)

Tel: 514-696-7961, Fax: 514-696-8344

Email: erwin@ddi.ca WebPage: www.ddi-heatexchangers.com