To view a heat-transfer efficiency comparison, click here.

“However, the system is more complex and requires greater operator attention, primarily in the equalization and heat-recovery steps and in ensuring continuous feeding of the raw solids. From the outset, plugging problems have plagued the spiral heat exchangers, …”

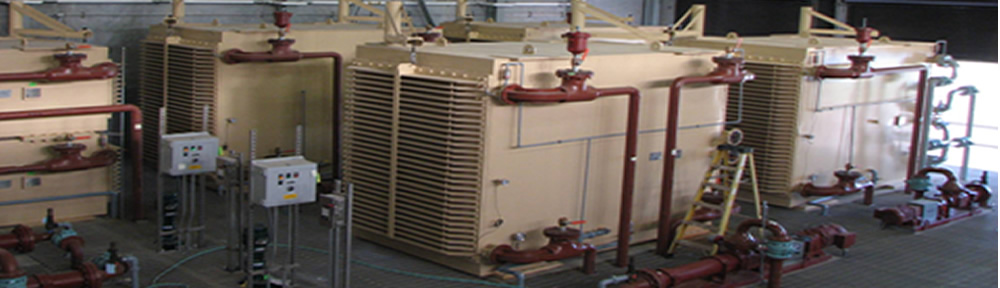

“In most early projects, conventional heat exchangers were used with little or no modification. Unless coupled with equipment that screens out debris, this arrangement may require frequent maintenance.”

“… the need for heat recovery, and the increased instrumentation and control required for advanced digestion will increase maintenance requirements for most facilities.”

AN ASSESSMENT OF AGRICULTURE CANADA’S

ANAEROBIC DIGESTION PROGRAM

Research Branch, Agriculture Canada

Engineering and Statistical Research Center

P. Van Die

“Fairly complex digestion system designs were developed. Manure screening is almost essential to prevent plugging and reliable components such as circulation pumps, heat exchangers and temporary biogas storages are essential. Current systems lack reliability and have high maintenance requirement.”

Sludge and Scum Screening At The Annacis Island Wastewater Treatment Plant

Contact: mahl@burnaby.associated-eng.com

“In 1991, the Greater Vancouver Regional district began design of the upgrade of the Annacis Island Wastewater Treatment Plant to secondary treatment. During the design, the District adopted a policy requiring that all biosolids generated from treatment be used beneficially. Removing debris from the biosolids is considered crucial to developing market acceptance of the product. In addition, removing or grinding material larger then 12 mm in the solids stream is required to avoid blocking process equipment. In North America, grinders are most commonly used to macerate sludge and scum. In Europe, screens with an opening size of 10 mm or less have been successfully used for removing debris from solids streams. The advantages of screening over grinding are lower capital cost if a significant number of grinders can be eliminated, a reduction in the quantity of debris entering the maintenance of equipment in the digester area, and less debris in the digested biosolids. Sludge and scum screens began operation in April 1996. This paper discusses the rationale behind the selection of these screening processes, the technology selection and design, and initial operation of the screens.’